Ready to Download!

Just complete the form to access your file instantly.

Are your maintenance methods missing these hidden warning signs?

The average manufacturing facility loses $260,000 per year to unplanned downtime that traditional maintenance approaches fail to prevent. Why? Because critical equipment failures rarely happen without warning—the warning signs are just invisible to conventional methods.

This exclusive guide reveals the seven most costly "hidden" failure patterns that cognitive maintenance systems can detect months before catastrophic breakdowns occur.

What You'll Discover Inside:

Early Detection Timeline: See exactly how many months earlier AI can detect each failure type.

Cost Comparisons: Understand the financial impact of early vs. late detection.

Visual Illustrations: Detailed diagrams showing exactly what these hidden failures look like

Real-World Examples: Actual case studies from manufacturing facilities that prevented major failures.

Implementation Roadmap: Practical steps to transform your maintenance approach.

Download the free 7 Hidden machine failures that cost you millions

(And How AI Spots Them Weeks Earlier)

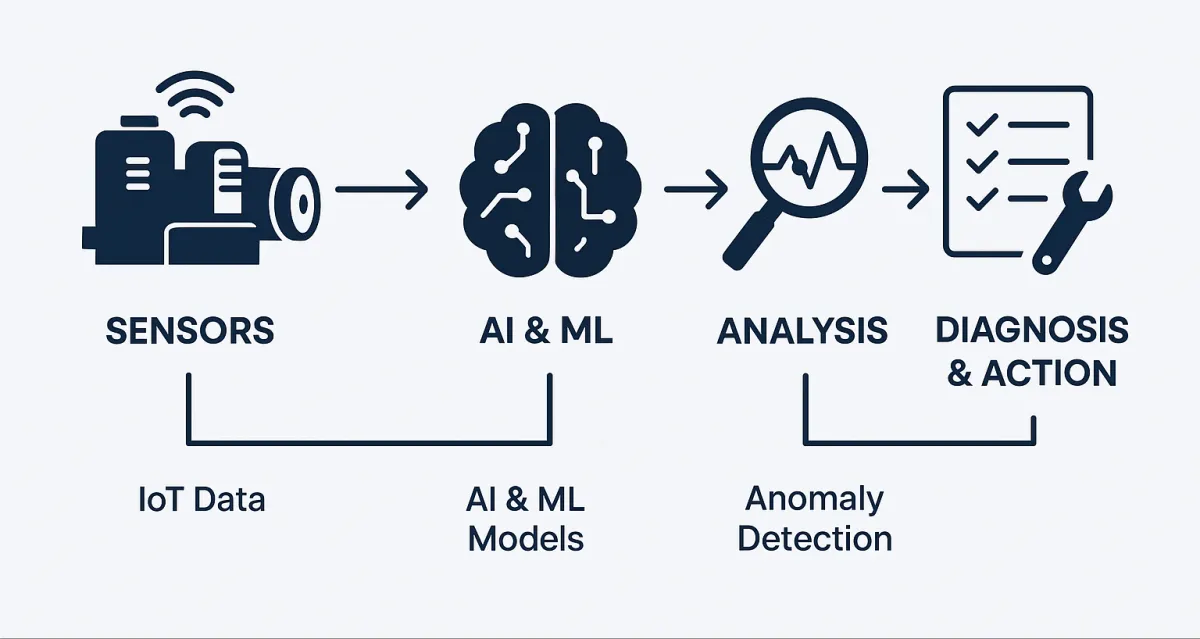

What is Cognitive Maintenance?

Cognitive Maintenance is an advanced form of predictive maintenance that uses AI, machine learning, and contextual machine data to not only detect and predict failures, but also to understand the root causes and recommend the best course of action—often automatically.

How It Works

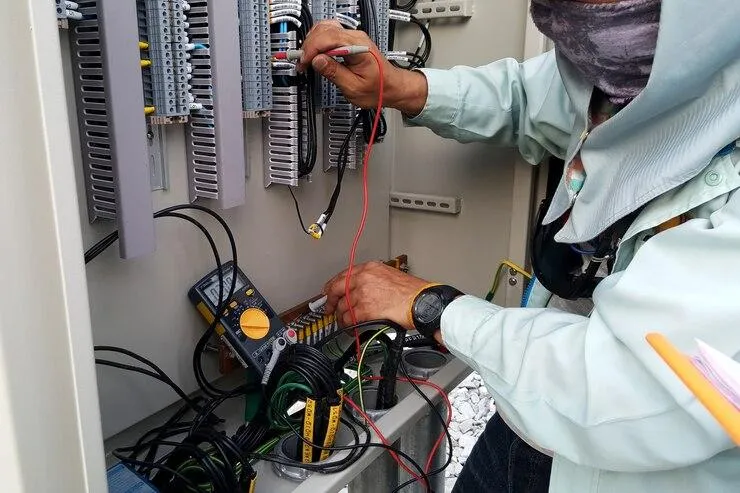

Sensors (IoT Data Collection):

Smart IoT sensors are installed on machines to continuously collect real-time data such as vibration, temperature, and sound.

AI & Machine Learning (Data Intelligence):

This data is processed through AI and ML models trained to detect unusual behavior and subtle patterns that indicate early signs of failure.

Analysis (Anomaly Detection):

The system identifies anomalies and performance deviations that human eyes may miss, often weeks before visible symptoms appear.

Diagnosis & Action (Smart Recommendations):

Cognitive Maintenance doesn't just detect problems—it diagnoses the likely root cause and recommends specific, data-driven actions to prevent failure.

Company

Solutions

Industries

Resources

Privacy Notice | Terms & Conditions

Copyright 2025 Groundup.ai All Rights Reserved